About the speaker:

Dagbjørn Skipnes conducts research in many fields related to heat treatment of food products, especially heat transfer, inactivation of microorganisms and heat-induced changes in quality. He is using this for all kinds of foods. In his current research, Dagbjørn focuses on seafoods like cod and seaweed. Based on the research areas he assists the food industry in areas ranging from documentation of heat treatment to production planning, including choice of methods and equipment for processing.

His professional background is in mechanical engineering and thermodynamics from NTH and doctorate was defended at the University of Life Sciences (NMBU), with the thesis “Optimization of heat treatment of fresh farmed cod.”

Company info:

Nofima is a leading food research institute in Norway that conducts research and development for the aquaculture industry, the fishing industry and the food industry. Their vision is “sustainable food for everyone”.

Presentation:

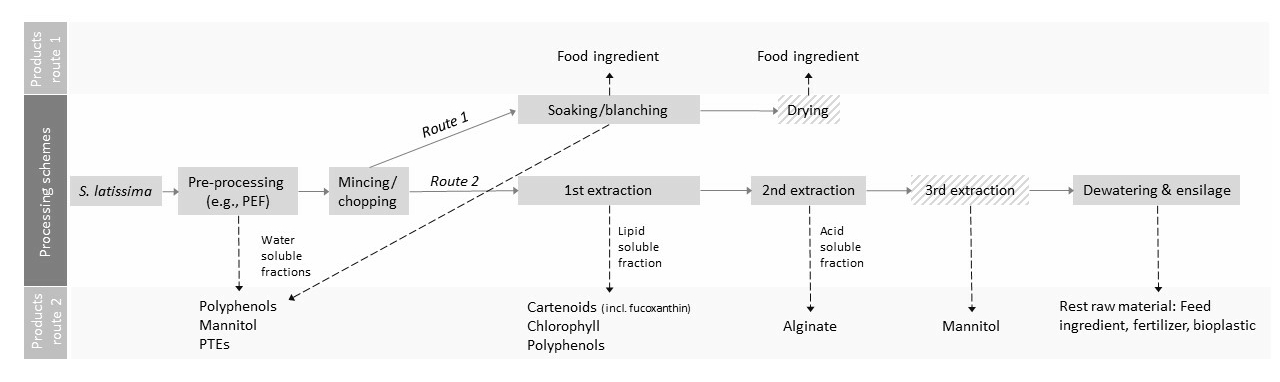

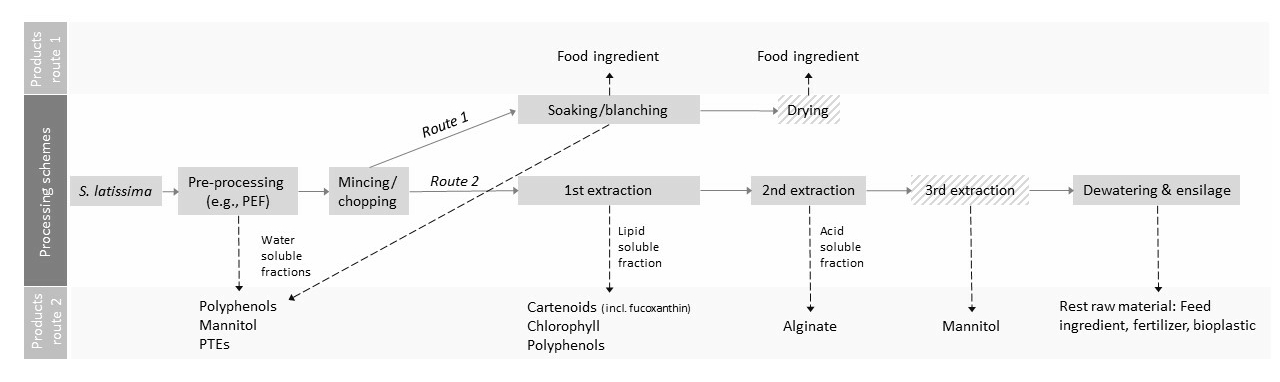

The European production of seaweed, including kelp species, is increasing. Efficient processing schemes for full biomass valorization are, however, still missing. The opportunities created by PEF with respect to extraction or further energy efficient processing are promising. PEF is well suited for continuous processing and may be combined with rinsing and low temperature blanching directly after harvest. The potential advantages are reduced shear force (easier cutting/grinding) and higher permeability which improves mass transfer during extraction processes or drying.

In recent studies, the effect of combining pulsed electric field (PEF) processing and soaking/blanching treatments (10, 45 and 60 °C) on the chemical composition of sugar kelp have been investigated.

The extracted dry matter increased for each processing step, and the combination of PEF and blanching gave highest yield (˜60 %) compared to only using one of the steps, (˜40 %). The extracted compounds analysed were ash (including iodine), polyphenols and mannitol. Proteins, heavy metals, other sugars and (presumably) fiber were concentrated in the solid fractions.

These results can be relevant both to researchers investigating novel technologies, processing of seaweed and food safety, and to the seaweed industry, for the selection of processing technologies and product applications.

Funding

The results are obtained from the projects SusKelpFood (Norwegian Research Council Grant no. 326803) and AlgaeProBANOS (EU project number 101112943), BEIS, funded by Nofima and the Research Council of Norway (grant number 194959), and the Nofima-funded project “PepTek”.